We interviewed Stacie Langtry, a veteran employee of Therm-a-Rest’s parent company Cascade Designs, and a talented engineer who has played a critical role in designing and bringing to market some of Therm-a-Rest’s most iconic sleeping pads. She offers a look into the day-to-day details of what it takes to innovate, the reasons behind Therm-a-Rest’s legendary quality for the past 50 years and much more. Enjoy!

Hello Stacie, do you mind introducing yourself and telling us your current position at Cascade Designs?

Hi, I am Stacie Langtry and I’m a Senior Product Engineer.

How long have you been with Cascade Designs and in what role did you start?

I have been at Cascade Designs for 15 years, and I started out as a Manufacturing Engineer in the factory. I was there for about five years, working on a variety of products across multiple Cascade Designs brands. After that, I moved into a Product Manager role for seven years, and now I’m back to creating great products for Therm-a-Rest as a Senior Product Engineer.

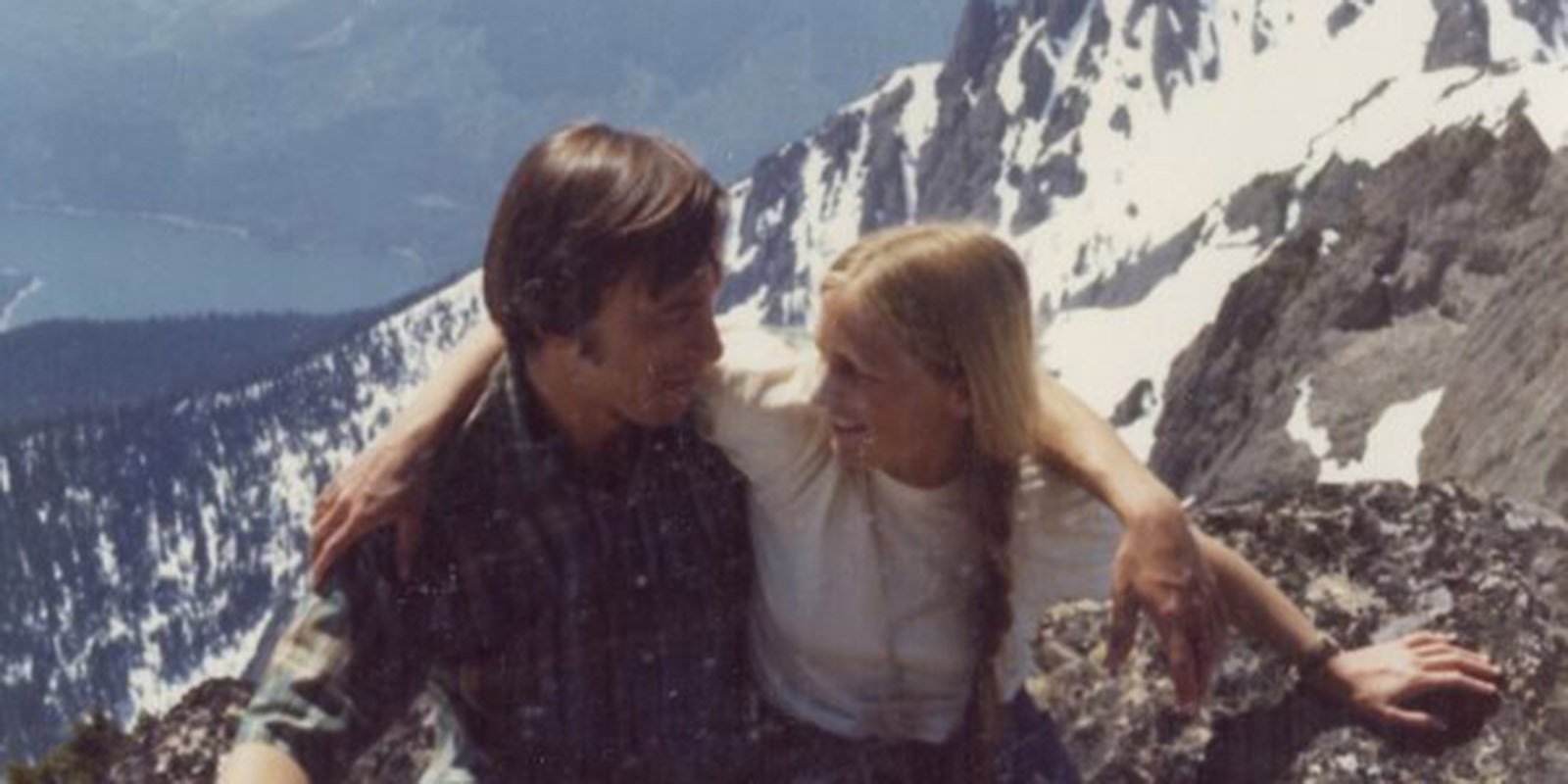

Stacie pregnant at work in 2008

Stacie pregnant at work in 2008Just to be clear, you deal significantly in the sleeping pad side of things, right?

Yes! Broadly put, right now, I am mostly working on the design and development of our self-inflating and air pads.

Here’s a fun question, what was your first ever experience with a Therm-a-Rest product?

I actually remember! The first Therm-a-Rest we got was in 1987, and it was actually my brother’s. We bought it at a scout shop in Ottawa and he used it for a bunch of scouting trips. I always had to borrow gear for my trips, including the pad, then around 2000 he gifted it to me!

So, I essentially used this pad from 1986 all the way until I started working for Cascade Designs. And I actually still have it, it’s in my garage. It’s old, it’s green and still great!

In your own words, what sets Therm-a-Rest sleeping pads apart from the competition?

I think what set’s us apart is quality. And I think a key way we achieve that is by having our own in-market manufacturing in North America and Europe. Right outside my office is where we make the Therm-a-Rest mattresses. We also make the equipment that makes them. So, we have full control of the manufacturing process from the beginning to the end of each pad.

We do a ton of testing here as well! We have a test lab on-site so that we know that each pad we design and build will meet our performance standards and last a long time.

You mentioned that we make the equipment that makes the pads. To what extent have you been involved in the design of the equipment? Can you give us an idea of the work you do with the teams and individuals that are responsible for designing and building our machines?

We start thinking about the machine side of things the moment we start working on a new project. When you’re still just in the idea phase about what you’re going to make, in the back of your mind you’re thinking about how it will come together in the factory.

From the very beginning, we will be collaborating with our colleagues that are in Manufacturing Engineering. Not only do we brainstorm the product, we are brainstorming the tiny details of how to make it too. The fact that I also started in that department gives me a good background to know all the equipment, the people that work on the equipment and what we are capable of in the factory.

You have been here for 15 years, which means you were here for the invention and launch of the NeoAir®. I know that the machines on the NeoAir lines are prized possessions and hold a special place here at Therm-a-Rest. Can you talk to us about those?

I remember when they first started talking about the NeoAir concept and the machine idea to make it a reality before it even had the name NeoAir. It seemed like a pretty complicated machine. They mocked it up, had one made with, like, wood, and it did make mattresses, but it wasn’t that great. I think we had to go through three machine iterations to get it going pretty smoothly.

For a while, I actually worked on one of the very first Neo machines as a manufacturing engineer. I still go out there today and there are some stickers on the machine explaining how you feed stuff through it that have my handwriting on them! When I see it I’m always reminded that that writing is over 10 years old, and thank god it’s still there so I can figure out how to operate this thing because of my notes from 10 years ago.

They are pretty unique and intricate machines. For the first couple of years, they were a little rough, but now they are working fabulously. It’s pretty cool to see them put together sleeping pads. New and exciting product is what our customers see, but there’s a whole world of new and exciting machines behind each one.

The NeoAir was a pretty significant innovation in the industry, spurring a significant swing towards air pads in the years after it came out. You drive innovation at Therm-a-Rest. What does innovation mean to you and how do you actually do it? How does innovation happen on a day-to-day level?

Innovation is driven by our customers and understanding what their needs are; knowing they want a great night’s sleep—they want to be warm and comfortable—and mastering all the details that make that possible. Having that mindset as we collectively brainstorm guides the massive amount of knowledge and creativity we have here.

We really have to listen to the feedback of those who have been out in the field and bring it all together to make a great product.

Therm-a-Rest has been committed to quality for the last 50 years. In today’s competitive landscape, how does Therm-a-Rest maintain its legendary quality especially given the current supply chain challenges due to the COVID pandemic?

One key is the close connection we have with our [manufacturing] workers here; some of them have been putting together pads for over 30 years. They have an eye for quality and will see stuff that no one else can. It really is like a family here. I remember when I first started here, they instilled the concept that quality is everyone’s job. Having people that are experts at what they do is essential.

That combined with it [manufacturing lines] being right near us here allows us to see any issues that might arise and make fast solutions to them. Defects happen, that’s just how it goes. With our manufacturing and rigorous testing being on-site, in the same place… it really shows in the quality of each pad we sell.

We work with some overseas suppliers of raw materials, but once the materials are here, we don’t have to work across oceans in terms of putting them together.

Exactly. We source all our own materials and have connections with our raw materials suppliers that maybe others don’t because they are manufacturing in a factory overseas and it’s the factory that has the connections to the suppliers. Here we have the direct connection. We can assess the quality of the materials coming in right away and see how good a supplier is.

Having been around for 50 years, I imagine we have learned some things and become pretty good at identifying good raw materials suppliers vs. the not so good, right?

Some of our suppliers have been around since the beginning, so the relationships have become very strong. I have some people that I worked with since I first got here and I am still working with the same supplier and their materials. Having that deeper connection and trust really matters to our ability to consistently make good products.

We also source a lot of materials from the USA. Having them closer makes collaboration and establishing that trust easier.

What has been your favorite project you have worked on for Therm-a-Rest?

Oh my gosh, I don’t know! I can’t think of one particular one, but the part I really like is ideating and making that first sample of a new product. I like trying new things, getting some materials and just saying, “let’s see how this goes!” When you have an idea—maybe you had it yesterday—and then you have the physical sample of it in your hand, it’s just awesome.

If I had to pick one, I guess working on the NeoAir has been pretty epic. If you think about it, the amount of years I have been here and work I have done on that… and it’s still going!

Without disclosing our secrets, what can we look forward to from Therm-a-Rest in the coming years?

We’re always looking at how to make our pads more comfortable for everyone, so you’ll see some innovation in that area coming from us. And, as always, we are constantly trying to make things lighter and warmer!

Lighter, warmer, more comfortable. That was the original mission of our founders 50 years ago, and we’re still going at it!

Exactly!

Well, that’s all the questions I have. Thank you, Stacie, for your time and 15 years of expertise!

Awesome, thank you!

Related Posts: