In celebrating 50 years of Therm-a-Rest awesomeness, reflection is a key part of the process. In doing so, we’ve had a blast looking back at all the cool things we’ve accomplished over the years and sharing them with you.

However, as awesome and transformational as our contributions have been, it’s important to remember that ultimately–real people, with names and stories of their own–have been responsible for everything we have accomplished. In that spirit, when we looked back on our most impressive and lasting innovations, the name Jim Marson was impossible to overlook.

Though recently retired in 2018, Jim’s 31-year tenure at Them-a-Rest resulted in what are arguably some of the most influential and lasting innovations ever made in outdoor gear. As the lead developer of both the NeoAir® and Z-Lite® pads, there’s a good chance you have him to thank for a lighter pack and more than a handful of comfortable nights in the backcountry. Honestly, if there was a Hall of Fame for gear designers, Jim would most certainly qualify for entry. With that in mind, we called the notoriously quiet and humble Jim out of retirement for a quick chat about his history, and what it was like to bring an idea as big as NeoAir® technology to market.

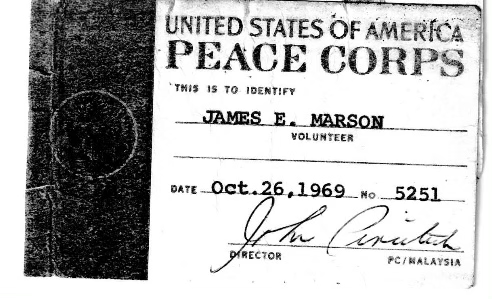

Jim grew up a local boy in Edmonds, Washington, just north of Seattle. He discovered his knack for tinkering while working in the local boat yard after high school. There he spent his days launching boats, pulling engines for repairs and moving boats around the harbor while beginning his college education at the University of Washington. After his junior year, he signed up for the Peace Corps and took his tinkering skills to Malaysia. “They were transitioning away from using water buffalo in the field and started using tractors, but they needed people to teach them how to fix them. That’s what I went over there to do,” reflected Jim. Two years later, Jim returned to the states to finish his Liberal Arts degree and even ended up doing some social work as a result of his Peace Corps experience.

Not surprisingly, his time in Malaysia had a transformative effect on him. In addition to instilling a lifelong travel bug, the immediate effect upon returning home was heading into the outdoors. Though he didn’t really consider himself “outdoorsy” growing up, his new thirst for adventure got him searching for more, and he found plenty in the mountains and along the coastlines of Washington.

Subsequently, he turned his engineering mind to outdoor gear, and some friends began building their own equipment. “We built and sold a few unique lightweight tents and snowshoes…we even developed plastic folding snowshoes that we pitched to Larry Penberthy,” he said, referring to MSR’s legendary founder. Penberthy wouldn’t take them up on the idea at the time, but the concept of plastic snowshoes would take the world by storm when MSR® released their version in 1987.

Indicative of Jim’s inquisitive nature, he “got sidetracked” for a bit working with a firm designing the iconic Lake Union houseboats (not really boats at all–just homes floating on concrete), all while researching and designing a modification to the rotary Wankel engine that would earn him his first patent.

“By the mid-80’s, I wanted to get back into the outdoor industry. I had always liked it, so I took my patent to a job interview in 1987 with Jim Lea, the co-founder of Cascade Designs, and was hired into the engineering group.”

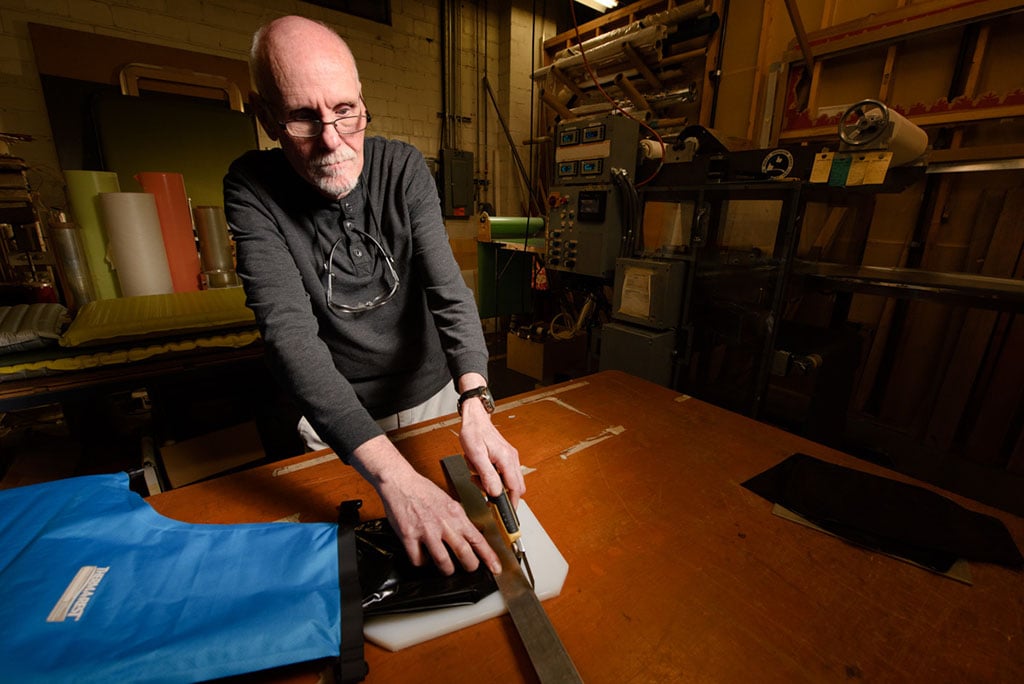

Because no one had ever built camp mattresses before, everything about the process of building and selling Therm-a-Rest pads was (and largely remains) homegrown. In fact, Jim’s first task as an Engineering Technician was to design and build the machines that rolled the new Therm-a-Rest self-inflating and foam pads tight for packaging. In those early years Jim recalls, “I worked on the development of our first wheelchair cushions [sold today under the VariLite™ brand], locking mechanisms for trekking poles and tons of other projects including mat puncture proofing, dry bag zippers and seals, and projects for NASA and the military.”

With little fanfare and a lot of humility, Marson also recounts designing the now-iconic Z-Lite® (then called the Z-Rest) folding foam pad that remains a staple of ultralight backpackers across the globe. Of course, in true pioneering fashion, he also helped design and build the machines that made them.

Of all the contributions to outdoor comfort that Marson has made, it might just be the NeoAir® pad that was his most significant. The idea of air pads for camping was beginning to gain traction in the mid-2000’s, but people were essentially using uninsulated pool floats and calling them camping mattresses. They were all the rage for a minute, but people quickly realized that they provided no insulation and were anything but stable to sleep on. While people were clamoring for these new, highly packable pads, Marson was quietly whittling away on an idea he’d had for years.

“The simple mechanics of Therm-a-Rests have always intrigued me. The off-the-ground support comes from the open cell foam being strong in tension to keep the air underneath the body from being displaced to another area. Because the foam has a lot of compressive memory, these mats are relatively bulky when rolled. I thought, why not make an air holding and warm mat with lots of strong tensile elements for off-the-ground thickness and stability and still have a lot of warm, air trapping convection cells,” says Marson.

Marson pitched the concept to the executive team and got the green light to start development on “Project Tiger” in 2005. Though it was talked about in hushed tones internally, people outside the project team didn’t really have any clue about what it was, other than “something big.”

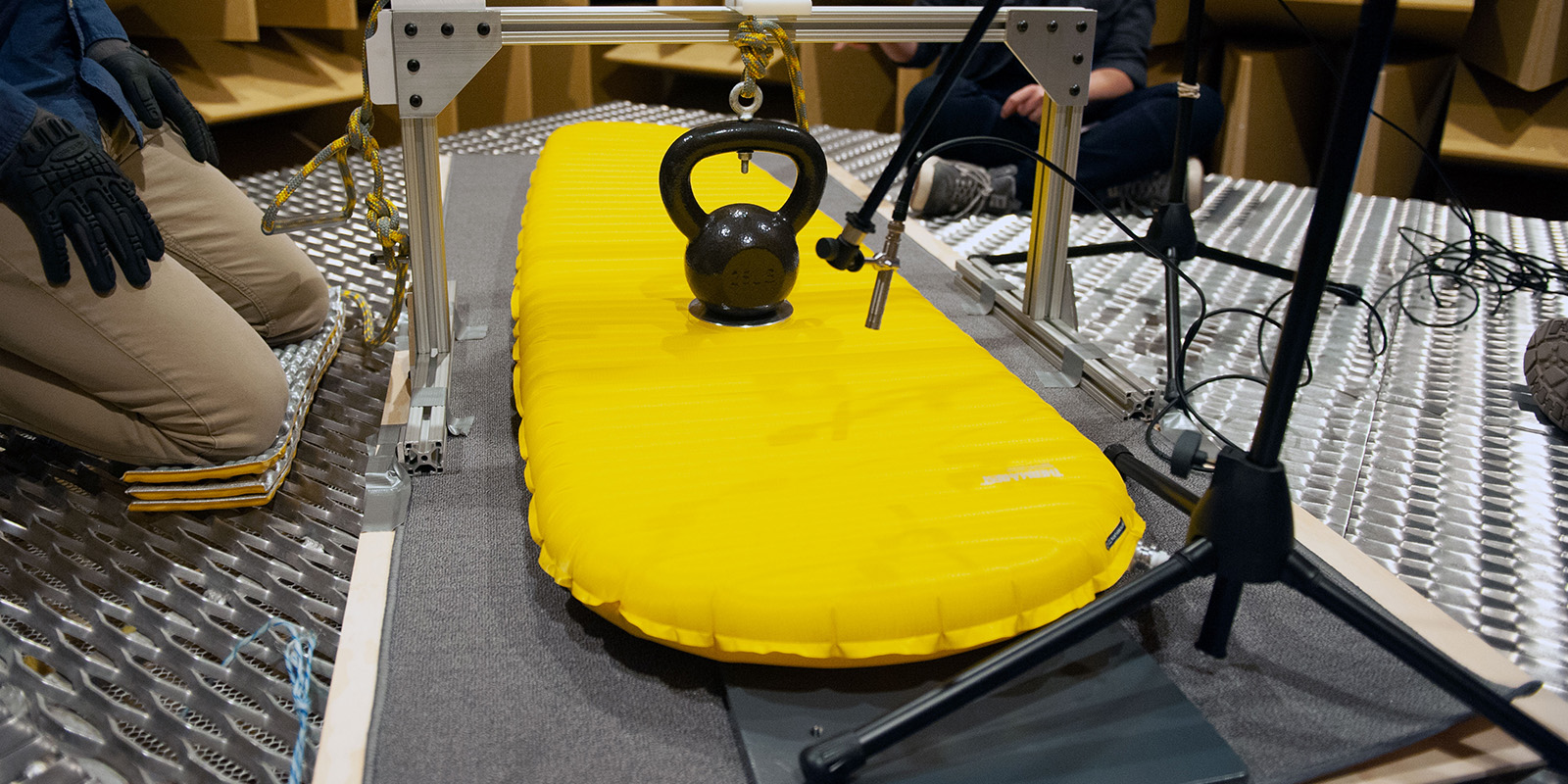

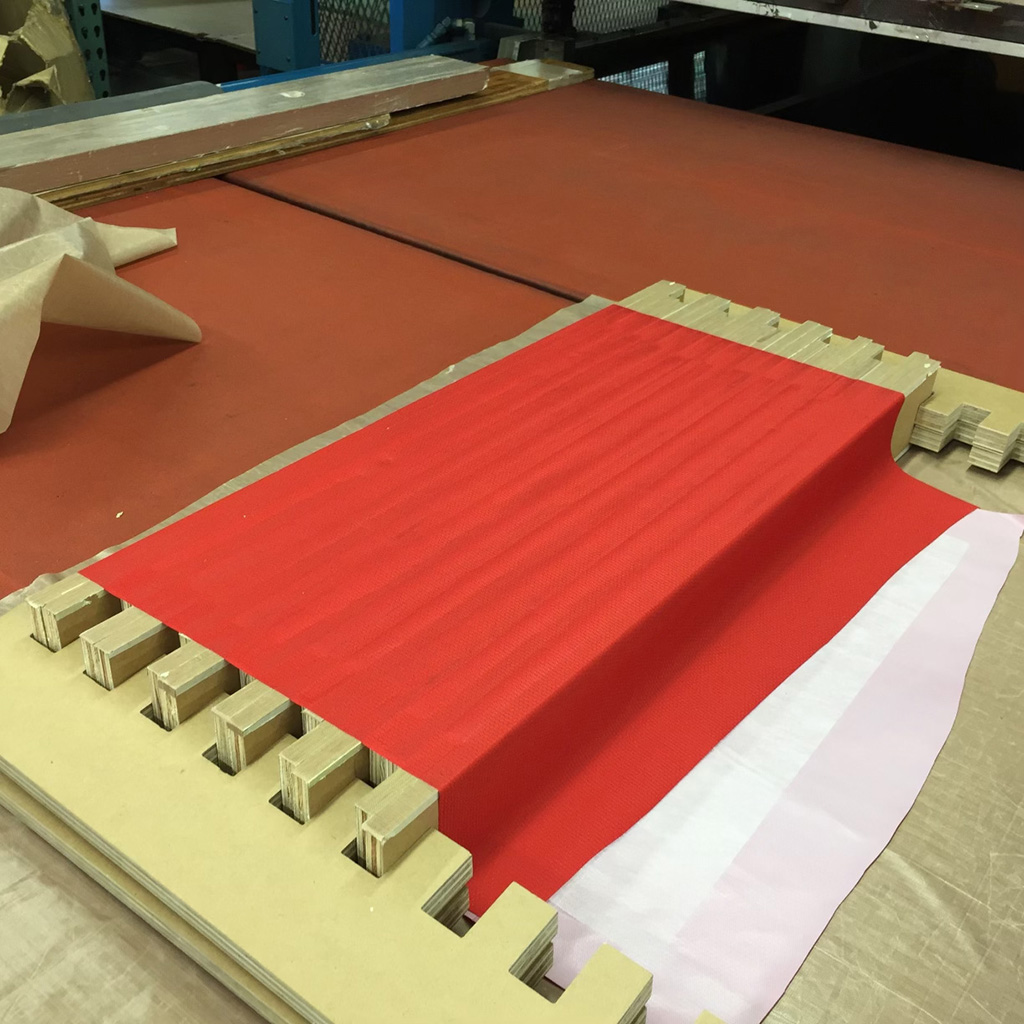

“The first challenges were to design an internal mat structure with fewer struts [than foam] that have the tensile strength, stability and near the thermal insulation of foam,” recalls Marson. For clarity, if you imagine a cross section of foam, the air cells are what trap air and provide most of the heat retention. The walls around those open cells are the “struts” that provide support, of which there are millions in a slab of foam. Marson’s goal was to replicate and simplify those properties by creating an internal structure of membranes, without any foam, leading to a much lighter and more compressible pad. So the core problem was not only designing that internal structure, but also finding one that had good thermal retention. Finding some way of bonding it together, then to a top and bottom layer of coated fabric and then sealing it all air tight would prove to be the crux of the entire project.

Marson still remembers the very first and important failures of the initial prototypes: “The first experimental mat cores we built were very stable but not layered enough internally to check thermal conduction from top to bottom. The final configuration, with two layers of triangular cells, did the trick and was amazingly stable. A layer of film positioned horizontally provided good a thermal convection barrier. Adding metallization to this and other layers increased the thermal insulation value even more with little to no weight penalty.”

With the thermal properties of the mattress dialed in, the team also discovered that running the welds horizontally–contrary to all air pads at the time–was also key. This pattern provided added stability and retained more width when the pads were inflated, meaning they could use less material to attain a wider mat.

Jim’s team worked tirelessly for years on Project Tiger before the first working prototypes began seeing real world testing for durability and function. While it was a challenge figuring out which of hundreds of materials worked best together in this complex structure, another team was busy building the machine that could do it from scratch.

“Finding a way to bond all the special layers together in an efficient way was a huge challenge and we tried several methods of doing this, finally settling on a bonding method used in the medical device industry. It was even more specialized for our configuration. We also were challenged by finding very strong, long-lasting, lightweight materials that would bond together in our equipment.”

Marson credits a talented and diverse team to being able to finally pull it all off. “Therm-a-Rest has a great set of developers, designers, engineers and machine builders, all thinking outside the box. We also have a good domestic supplier network that enabled us to not just find the optimum materials, but to build the correct machines from the right machine parts. Having very smart production people on the factory floor that can spot and solve problems is a huge advantage too.”

In late 2008, the first customer-ready Therm-A-Rest NeoAir pads began to roll off the line and were sold into stores in the Spring of 2009. The accolades rolled in swiftly, and the NeoAir pad became the number one selling camping mattress in short order.

I wondered if Marson, having built something that revolutionized the way people sleep outside, was aware of the impact Project Tiger would eventually have while he was working on it.

“Probably not. I just wanted to introduce a lightweight, warm and small pack-size mat to complement other Therm-a-Rest products. It’s great that it’s being copied to some extent–but not too closely! I am proud that the most relevant U.S. patent of the project is hanging on the wall, upstairs in my home office, along with a Cascade Designs Board of Directors Innovation Award.”

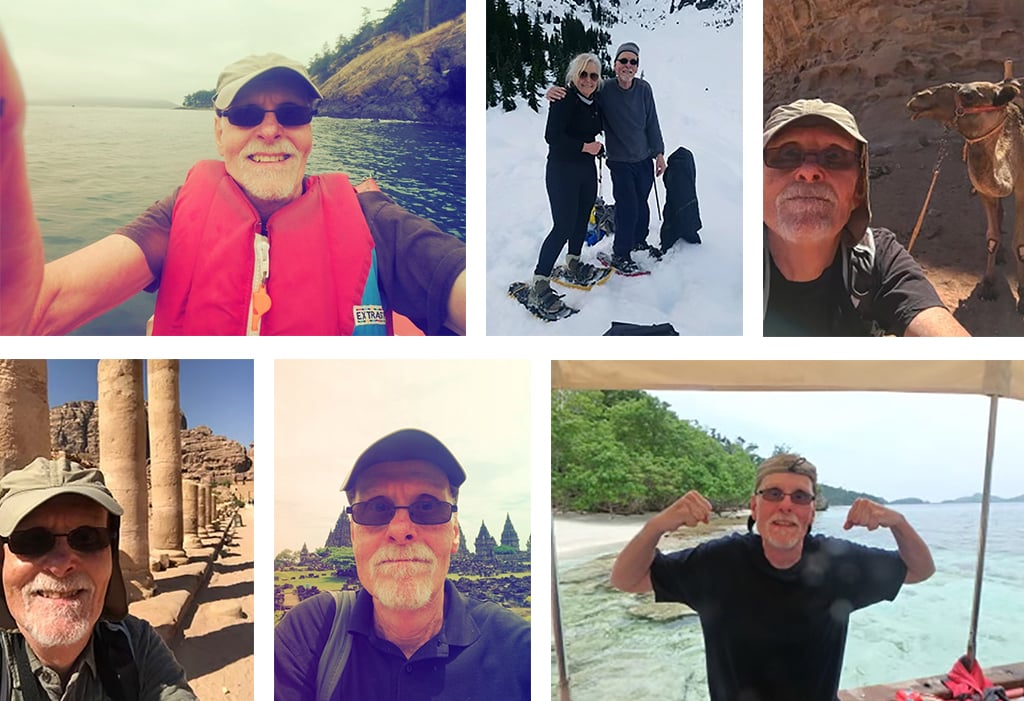

When Marson retired in 2018, he left behind a legacy of 11 utility patents (patents awarded for how something works–not just how it looks), with five more granted after his retirement for a total of 16–a truly grand accomplishment in the outdoor industry. He still lives in the Puget Sound area, hiking and sea kayaking and looking forward to more of his favorite thing–globetrotting on the cheap.

“I’ll always be a Peace Corps volunteer at heart, I think,” he said.

For someone that bounced around as much as Marson, it’s safe to say that he found a welcome home at Therm-a-Rest, where his talents could truly shine, and that we can all be thankful for.

So, maybe the next time you snuggle into your bag or blanket atop a cushy Therm-a-Rest air mattress, just before you drift off, you can send a little, “Thanks, Jim” into the night sky. I think that’s all the public recognition Jim Marson could ever ask for.

#ThanksJim

Related Posts: